Automation for the food industry

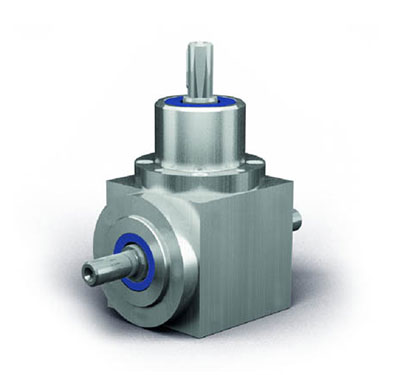

Food-safe and efficient integrated drive solutions that meet the highest hygiene standards and are highly resistant to corrosion, acid and alkaline dust.

BEGE: automation partner for the food industry

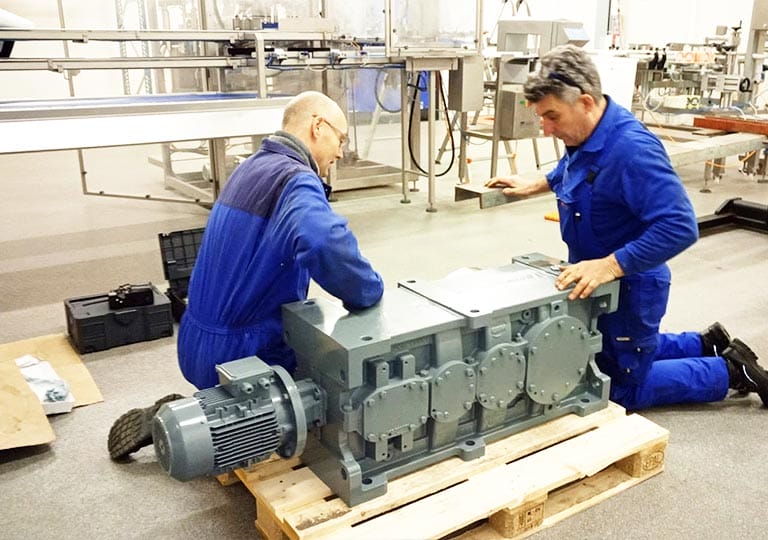

BEGE supports machine builders, manufacturers and other players in this sector with optimal automation solutions. Our extensive knowledge of the industry enables us to always deliver a suitable drive or controller.

Co-engineering for drives in the food sector

We are one of the few suppliers on the market that works closely with our customers’ professionals. Through co-engineering, we work together to create smart and efficient drive and control solutions for the food industry. As an automation partner, we are also involved in making the food industry more sustainable in terms of drive technology. For example, we supply food-safe stainless steel electric motors.

It’s not about what we make, but about what we make possible.

Automation for the food industry

Custom drives for the food industry

We develop and manufacture custom drives and automation solutions. Together with our customers in the food industry, we have already developed many tailored solutions. A number of applications are shown below. Move over an area to read more details.

Filling bottles without foaming

Beverages & bottling

Filling bottles without foaming

Wish: Accurately position bottles in a filling machine to reduce foaming. Solution: To fill carbonated beverages at exactly the right angle, we position the bottle neck with a worm gear motor driven by a MIG encoder.

Coil freezer and cooler

Fish & meat processing

Coil freezer and cooler

Wish: Drive modular loading systems for optimum product flexibility of hygienic spiral freezers and chillers. Solution: Stainless steel drives with -40°C NOTOX oil maintain drive efficiency in these harsh conditions and ensure continuous operation.

Sieving and washing vegetables with adjustable butterfly valves

Vegetable & fruit processing

Sieving and washing vegetables

Wish: Precisely adjust individually adjustable butterfly valves for correct flow rate.

Solution: Electrically driven butterfly valves with MIG encoder feedback. Precision adjustment ensures optimum turbulence and flow rate to thoroughly clean vegetables.

Stainless steel spindle lift drive for bottle cleaning

Beverages & bottling

Stainless steel spindle lift drive for bottle cleaning

Wish: Accurately position lift platform to guide recycled bottles through cleaning machine.

Solution: Mechanically linked spindle lift drives hygienically integrated into the machine. Stainless steel spindle lift drive can easily be cleaned in daily cleaning cycles.

Portioning sausage fillings

Fish & meat processing

Portioning sausage fillings

Wish: Drive meat mills and portioning machines for accurate portioning or filling.

Solution: Matched machines with synchronous VFD and MIG encoder. User-friendly HMI makes adjustment easy for different portion sizes or sausage types.

Positioning bottles

Beverages & bottling

Mechanically aligning bottles

Wish: Precise mechanical alignment of PET/glass bottles, vials, jars and cans. Solution: Spiral drive line for filling preparation in automatic high-speed filling systems. Drive line runs 24/7 and monitors power consumption and temperature to promptly signal anomalies.

Flexible vegetable cutting

Vegetable & fruit processing

Flexible vegetable cutting

Wish: Cut various vegetable products such as cabbages, onions and paprikas. Solution: HMI touchscreen for correct setting of wing knife speed. The continuously adjustable belt cutter wing knife is easy to control and change between products.

Brewing machine speed

Beverages & bottling

Brewing machine speed

Wish: Control correct speed of pump and mixing system for brewing machines where hopped wort is produced.

Solution: MIG encoder feedback and HMI monitoring for correct speed setting. Different cycles can easily be programmed and run automatically with a PLC.

Monitoring for delicate fruit

Vegetable & fruit processing

Processing delicate fruit

Wish: Peel, pit, slice or de-stem soft fruit.

Solution: Careful stepwise handling of fragile fruit by monitoring and built-in safety functions (software and hardware).

Rotary bottle sorter

Beverages & bottling

Bottle sorter

Wish: Drive a rotary bottle sorting machine to sort and transport unsorted PET bottles.

Solution: Reliable continuous-duty three-phase motors move bottles to the production line. VFD platform speed can easily be adjusted to suit the type and number of bottles.

Driving IP69K cutting blades

Fish & meat processing

Driving IP69K cutting blades

Wish: Drive for cutting poultry on an automatic processing line with strict hygiene standards.

Solution: A V19-mounted IP69K stainless steel motor with drain channels to discharge waste and water and protect vital seals.

Vibration system for efficient blanching

Vegetable & fruit processing

Vibration system for blanching

Wish: Efficient, high-quality blanching using water, steam or spraying. Solution: Conveyor with a vibration system to separate and blanch vegetables for ready-to-eat meals. The VFD conveyor provides the right processing speed for perfect blanching.

VFD drum motor

Fish & meat processing

VFD drum motor

Wish: Automatic deboning, descaling and peeling of fish and seafood. Solution: Conveyor with integrated drum motor and pressure rollers. VFD drum motor allows the speed to be matched to the product quantity and shape.

Flexible vegetable sorting

Vegetable & fruit processing

Flexible vegetable sorting

Wish: Flexible sorting of dried fruit, carrots or courgettes with variable shape and weight.

Solution: A VFD conveyor for gravity sorting machines with adjustable speed. The HMI is easy to operate and set to the right speed.

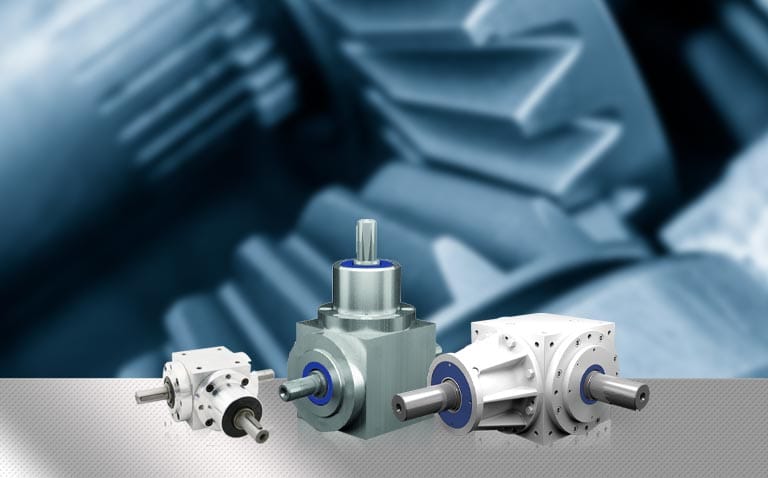

Hygienic molding machine

Fish & meat processing

Hygienic molding machine

Wish: Continuous hygienic drive of forming machines for chicken nuggets, fillets and steaks.

Solution: A rotating drum driven by stainless steel bevel gear motors. Withstands daily high-pressure cleaning to combat bacterial contamination.

Swipe ->

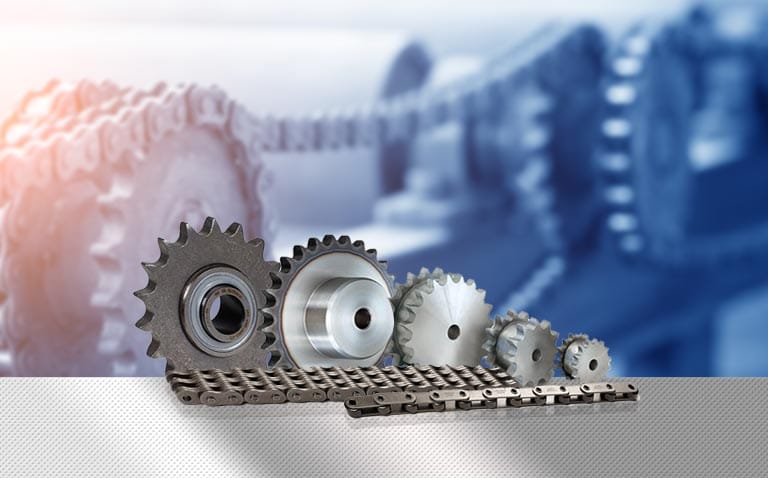

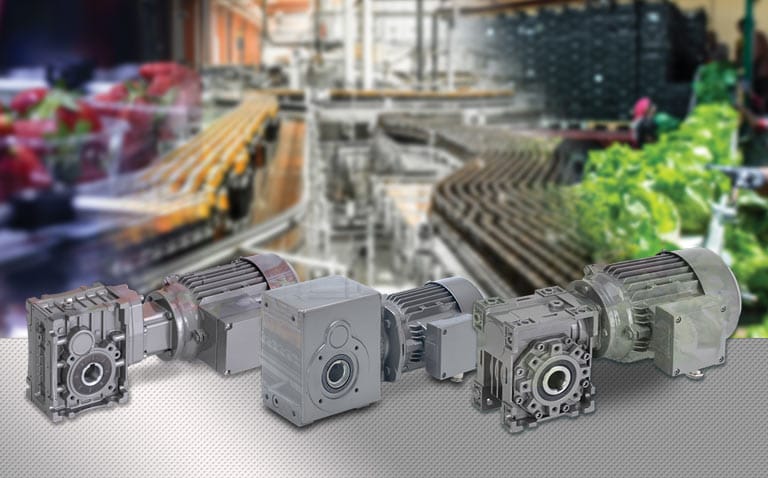

Drive components for the food and beverage industry

Automation in the food industry

Our drive and control systems for the food and beverage industry are highly suited to humid conditions and meet the strictest hygienic standards.

Satisfied customers in the food industry

Related topics and developments

Attractive products and comparisons for the food industry.

Want to know how our food-safe automation solutions can help you? Feel free to contact us.