Custom Drive Solutions

Innovation at the component level within an integral drive system; from standard to customized and from small to large.

Specialized, Customer-specific Drive Solutions

With years of experience in drive technology, BEGE not only supplies the parts, but also offers innovative customized solutions tailored to sector- or customer-specific requirements. Whether it’s a small, compact machine or an extensive, complicated system; when it comes to industrial manufacturing we can provide the answers to today’s challenges and tomorrow’s desires.

From supplier to innovator at the component level

BEGE was founded in 1950 as a supplier of components for power transmission. Over time, we started producing components such as the G-serie helical gearmotor and the MIG NOVA+.

In line with our mission of creating, optimizing and maintaining reliable drive systems, our services have shifted from being a pure supplier and manufacturer to being an integrated drive partner.

By combining various components into a customer-specific integrated drive system, we have successfully assisted countless companies in professionalizing their drive processes in recent decades.

Over the years, BEGE has increasingly focused on the innovation of customization at the component level. This means we select the best version of a specific component to fit perfectly within the machine. We cleverly combine and innovate existing technologies and deliver integrated technical customization to improve the drive process.

Modifications for Drive Systems, Products and Components

BEGE provides specialized customization in power transmission. Move the mouse over the labels to see all possible versions.

Frequency inverters (VFDs)

- Control technology: V/f, FOC, SVC (sensorless vector control)

- Safety: Standard, STO (Safety Torque Off)

- Display: LED, LCD

- Optional cards: Relay card, I/O card, TTL/HTL Encoder card, Resolver card, I/O plus card, CANopen interface, PROFIBUS interface, Multi-Ethernet interface

- Protection (IP-class): IP20, IP54, IP66

- Accessories: Shield plate, Brake chopper, Mains filter, Dust cover, Connection cable

PLC’s

- Programming languages: Redundancy System (XGR), Ladder Programming (XGK), IEC Standard Programming (XGI), Terminal Block (XGB-U), Connector (XBM)

- Communication: Ethernet, Ethernet I/P, CANopen, Profibus-DP, DeviceNet, RS-232C, RS-422/485

- Inputs/Outputs: 8 / 16 / 32 / 64 points

- CPU speed: 28 ns/step – 160 ns/step

- Max. I/O control: 256 points – 131.072 points

Human Machine Interface (HMI)

- Screen size: 4.3 inch, 5.6 inch, 5.7 inch, 7 inch, 8.4 inch, 10.4 inch, 12.1 inch, 15 inch

- Resolution: XGA (1024 x 768), SVGA (800 x 600), WVGA (800 x 480), VGA (640 x 480), QVGA (320 x 240)

- Versions: Premium, Standard, General

- Interfaces: Ethernet I/F, Serial I/F, USB I/F, SD/CF Card I/F, HDMI I/F

- Protection (IP-class): IP65, IP66

- Logo: Company logo possible

Electric motors

- Motor type: 1-phase induction motor, 3-phase asynchronous AC-motor, 3-phase synchronous motor, Servomotor, Brushless motor, PMDC motor

- Efficiency class: IE3, IE3, IE4

- Protection (IP-class): IP55, IP56, IP65, IP66, IP67, IP69K

- Isolation class: 155 (F), 180 (H)

- Material: Aluminium, Cast iron, Stainless steel (INOX)

- Certificates: CE, CCC, UL/CSA, ATEX, DNV-GL

- Motor construction type: B3, B14A, B14B, B5, B35, B34

- Motor protection: Bimetal, PTC, PT100, Anti-condensation heater, Condensation drain

- Cooling: IC410 (TENV), IC411 (TEFC), IC416 (TEFV), IC418 (TEAO)

- Brake: DC-brake, AC-brake, double brake

- Bearings: Standard, Reinforced bearings

- Coating: C1 – C5-M / IM1 – IM3 (ISO 12944-2), FDA-approved

- Shaft configuration: Special shaft dimensions, 2nd shaft, Speedi-sleeve

- V1 protection: Rain cover

Flange encoders (MIG)

- Positioning: Incremental, Absolute

- Interface: HTL, TTL, BiSS, SSI

- External evaluation: NPN, PNP, RS422

- Impulses / rotation: 1 – 2048

- Resolution (bit) (absolute version): 4 – 18

- Flange design: IEC, NEMA, Cover, 4-pins cable

- Material: Aluminium, Stainless steel (INOX)

- Shaft opening: Custom shaft opening based on rotor shaft diameter

Gear units

- Transmission: Helical Gear, Helical Bevel Gear, Hypoid Gear, Planetary Gear, Shaft Mounted Gear, Servo

- Material: Aluminium, Cast iron, Stainless steel (INOX)

- Installation: Feet and/or flange

- Shaft configuration: Custom shaft dimensions, multiple shafts, hollow shaft, Stainless steel shaft

- Lubrication: Original BEGE GearOil, NOTOX/H1 (FDA-Approved)

- Bearings: Standard, Reinforced bearings

- Coating: C1 – C5-M / IM1 – IM3 (ISO 12944-2), FDA-approved

Specialized Integral Drives

Our drive systems lead to optimal drive processes thanks to innovative customization.

Smart Food-safe Drive Solutions

As a result of increasingly strict legislation, organizations in the food industry must meet strict requirements, whether or not a drive comes into contact with food. BEGE collaborates with machine builders and other companies active in this sector to offer customized, smart, food-safe drive solutions.

Our stainless steel product line takes the customer’s specific situation into account. We create stainless steel drives for applications requiring the highest hygiene standards, without compromising on quality, reliability or performance. These drives are often placed in installations where extremely high humidity levels and frequent cleaning cycles regularly occur, such as breweries, meat and poultry processors and dairies.

In addition, we also supply stainless steel drives for situations where there are no harsh conditions or high-pressure cleaning, but where regulations imposes requirements on food safety. These more basic drives are used, for example, in conveyors for bread baking machines.

We also supply aseptic motors with special coatings for use in the food industry. These motors are often used in combination with an aluminium gearbox and feature a food-safe coating. The motors have the same design as the stainless steel motors, but are lower cost and lighter thanks to the choice of materials, which makes them easier to use.

Protection rating range IP55, IP56, IP65, IP66 and IP69K.

High-precision Drive Components for Motion Control and Servo

We supply a wide range of KHK gears and racks for motion control and servo. The high quality and optimum precision of these components lead to very accurate positioning with little play.

We have a large stock, so we can guarantee short delivery times. We can produce these parts to size as required, tailored to customer-specific needs such as surface finish and heat treatments, tooth shapes and tolerances.

We also work closely with our suppliers on new products that lead to more efficient drives.

ATEK has recently launched a new series of planetary angle drives specially for the motion control and servo market. BEGE is the official representative in Benelux. This expansion allows us to provide our customers with planetary drives for dynamic applications.

These drives are compact and easy to use in small machines with limited installation space. Customers are regularly amazed how much more compact the final drive turns out to be than they initially thought possible.

Curious about how our customized drive systems can help your company?

Make an appointment with our engineers.

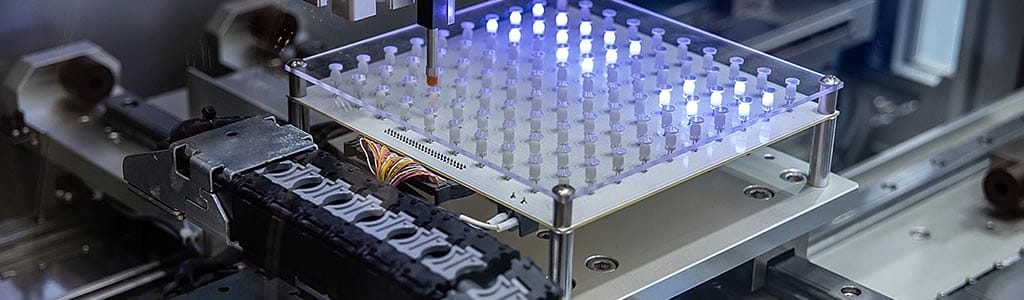

Modern Workplace

With our own engineering lab, test facilities and spacious workshop, including a semi-automated paint shop, our certified technicians have access to all the tools needed to design, adjust and maintain high-quality drive systems.

Here we realize customer-specific solutions, such as customized drives, specific drive components, hypoid, worm gear, bevel gear, right-angle or planetary gear motors.

Drive Partner for Customization

BEGE offers advice, guidance and delivery of innovative, customized solutions for power transmission. We ensure that the drive systems that we deliver seamlessly connect to our customer’s business processes.

Our advice is always independent because we are not tied to a single supplier. We combine components from various quality suppliers into an appropriate drive system.