LS VFDs

Powerful and compact VFDs for speed control, optimal motor performance and energy savings.

LS VFDs for energy-efficient drive systems

Frequency inverters are an increasingly important part of optimizing motor performance and machines. BEGE supplies powerful and compact variable frequency drives from LS Electric.

Why use a variable frequency drive?

There are various reasons for using a VFD: to control the speed of an electric motor, improve process control, reduce energy consumption and generate energy efficiently, or to reduce mechanical stress in motor control applications.

System optimization

When designing an installation, it can be challenging to comply with energy efficiency regulations.

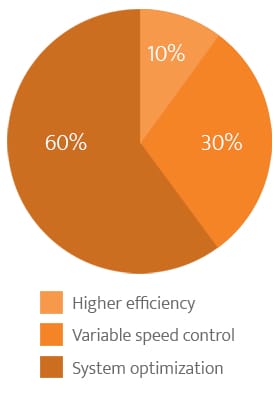

If the total potential savings that can be achieved in a drive system are set to 100%, approximately 10% can be achieved by selecting components with higher energy efficiency. For example, by switching from an IE2 motor to an IE3 motor or higher. Of the potential energy savings, 30% can be achieved by operation with variable speed control. However, the greatest savings, approximately 60%, can be achieved by optimizing the entire system.

Together with our customer, we co-engineer the machines and industrial processes to achieve the best results. We analyze the entire system and advise which components should be used.

Benefits of variable speed control

Variable speed control at BEGE

Are you currently using an electric motor with a drive but not satisfied with its efficiency? Do you want to improve the energy efficiency of a machine? Or would you like to upgrade your installation?

Switching to an LS VFD

Is switching to variable speed control difficult and complicated? Not with BEGE.

We have years of experience and know that every customer has their own unique process. We design a unique drive to meet their needs and requirements.

The configuration and dimensioning of the controller depend on the application and environment, so we always start with an evaluation of the application before the design and energy-saving phase. Whether it’s improving the energy efficiency of a new machine or an existing machine, we always look at the entire system.

BEGE provides LS inverters, where simplicity, precision, flexibility and ease of use are key features. We have the right variable frequency drive for every application (fan, pump, elevator, cleaning environment (IP66), etc.). The wide range of LS products consists of control components, including HMIs, PLCs and motion controllers, that can be perfectly matched for optimal control.

Consulting & support

At BEGE, we know that the manuals of many suppliers are not clear. And because knowledge is essential for the correct installation of a variable frequency drive, our service goes far beyond simply supplying the drive.

We are well known in the market for our personal support. We provide extensive support for programming PLCs and frequency inverters, linking all software to the drive and control components, and fine-tuning automation processes.

Other service benefits of BEGE:

- Quick delivery thanks to inventory in Sassenheim

- Drives up to 22 kW are available from stock

- Direct follow-up of technical questions or problems

- Easy assistance through our online channels

- Long-term component availability

- Fast repair or delivery of spare parts

- Tailored options

Selecting the appropriate VFD – 5 factors

What makes a frequency inverter suitable for a specific drive? It can be tempting to select a VFD based solely on motor power, but there are other, more important considerations. We’ve listed five relevant factors below:

1. Application

Some applications require a specific power curve. It is important to pick a variable frequency drive that can meet such requirements. A pump, for example, will start up slowly due to the resistance of the liquid.

2. Maximum current

Check the motor’s nameplate for the maximum Full Load Amperage (FLA) and then pick a VFD capable of supplying at least this amount of current.

3. Overloading

Some applications will briefly require more (starting) torque or are subject to cyclic overloading. In these cases it’s best to pick a VFD capable of handling the drive’s specific demands.

4. Height

In principle, all frequency inverters are air cooled, which means they are influenced by the atmospheric pressure and ambient temperature.

VFDs installed at heights over 1000 m may experience cooling issues. It is strongly recommended to pick an inverter that is powerful enough to compensate for the lack of cooling.

5. Temperature

Frequency inverters generate heat that, if not sufficiently dissipated, can cause equipment to shut down or worse, sustain damage.

If the environment exceeds the manufacturer’s specified maximum operating temperature, additional ventilation or cooling of the variable frequency drive is crucial.

Powerful and compact VFDs from LS Electric

We supply LS Electric products for VFD applications. These inverters are used in a variety of applications, such as cranes, elevators, steel production and water treatment plants. All LS inverters comply with strict quality, environmental and international requirements.

Benefits of LS variable frequency drives

- Powerful performance

- Compact and space-saving

- Easy to use and easy to connect

- IP66 / NEMA 4X version

- Standard safety features

- Multi-smart copier for fast and easy on-site software provisioning

- Improved torque performance thanks to powerful sensorless vector control

Technical features

- Power range: 0.1 to 500 kW

- Robust power at low speed: starting torque 200% at 0.5 Hz.

- Motor temperature monitoring without motor sensor

- High overload capacity: 150% for 60 seconds and adjustable from 5.5 kW to 120% for 60 seconds in normal use (ND mode).

- Extensive connectivity to various field buses (Profibus, Ethernet IP, Modbus TCP, CANopen, EtherCAT)

Your Reliable Partner in Drive Solutions

We make life easier for industrial enterprises by creating, optimizing and maintaining high-quality drives.

LS VFDs: the different series

Our LS portfolio includes four different series of frequency inverters.

LS VFD High Performance – S100

The S100 series is a general-purpose industrial VFD with V/F and sensorless vector control, available from 0.5 to 100 HP. This drive is double rated for constant torque and variable torque.

- Powerful performance

- Compact design

- Easy to use

- Standard compliance

- Safety features

The S100 is also available in an IP66 / NEMA 4X version (external power disconnect switch) and an IP66 / NEMA 4X PLUS version (external circuit breaker, 3-position switch and potentiometer) for optimal protection against substances such as fine dust and high-pressure cleaning.

This fully integrated VFD does not require cabinet mounting. This results in considerable savings in installation time and costs.

LS Fan & Pump VFD – H100

The H100 series is specifically designed for use in HVAC, ventilation and pump drives.

Programmed start-up and stop curves to accommodate large pressure differences and thus prevent damage to the pump.

The H100 is energy-saving due to flow compensation for long pipes, for instance. The H100 hardware and software are specifically designed to make the pump and fan control processes as efficient and sustainable as possible.

- Maximum ease of use

- Efficient space use

- Stable system control

LS Micro VFD – M100

The M100 is an excellent choice for small motor applications. These controllers can be mounted side-by-side with only a 2 mm gap.

Despite its small form factor, the M100 offers many functions, can be mounted on a DIN rail, and complies with UL 60800-5-1.

The M100 Micro variable frequency drive from LS features:

- Built-in C2 EMC filter

- User-friendly design

- New UL 61800-5-1 design

- Built-in DB unit: ≥ 1.5 kW

- Modbus advanced I/O

LS Compact VFD – G100

The optimal choice due to its strong sensorless vector functionality, enhanced performance and outstanding quality that meets high reliability standards.

The dual classification enables a wide range of applications for the drive, and the user-friendly design makes it easy to install, operate and maintain.

- Very reliable

- Powerful performance

- Easy to use

Need help selecting the right LS VFD for your installation?

Request a no-obligation consultation with one of our engineers.