For machine building and process automation, we provide reliable controllers for the efficient and powerful

performance of a machine or production line.

Does your machine require a highly compact drive? Greater efficiency? Are you aiming for a streamlined production process thanks to higher dynamics, greater precision and higher accuracy? Are you thinking about using robotics or cobotics in a production line or machine?

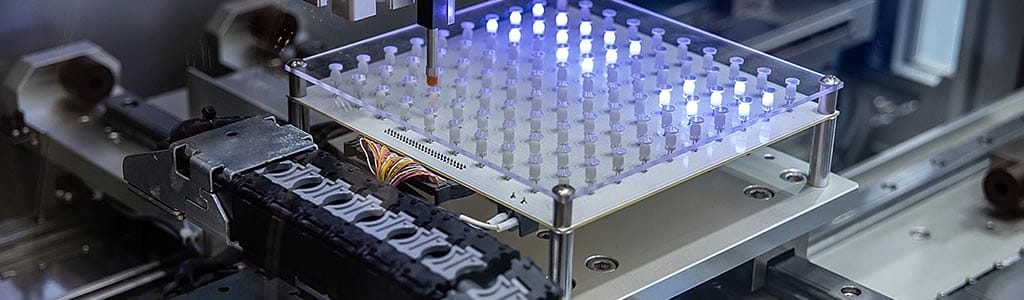

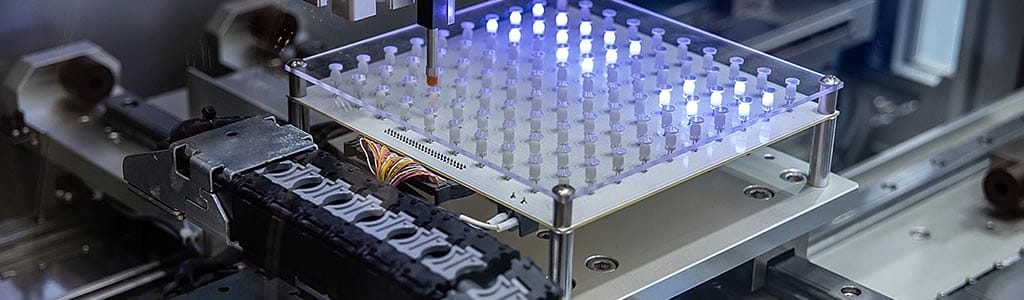

Perhaps the key to solving your challenges lies in servo engineering and motion control. With servo technology, we offer a high-end solution that offers more than just the drive function: it is about dynamics and control of the drive system.

Compared to traditional drive and automation systems, a servo drive system has the following distinguishing features:

Our customers integrate servo technology in the development or modification of their machines in a wide range of applications:

Whether it’s a servo system, a traditional drive system or a complete automation solution: BEGE offers the full solution. As an industrial automation specialist, we provide reliable controllers for efficient and powerful machine and production line performance.

BEGE does more than just supply and distribute servo drive systems. Using advanced technologies, we engineer complete and integrated servo drive solutions that help to create efficient installations with maximum reliability. From low-cost servo drive systems to high-end multi-axis systems.

For this we draw on an extensive portfolio of servo motors, servo gear units, servo drives and HMIs from our highly reputable partners Atek and LS Electric.

Thanks to continuous market-oriented process innovation, the servo components can be perfectly combined to form intelligent drive systems, where we can guarantee that all the components fit together seamlessly. Contact with a single partner keeps everything straightforward.

We understand that complex servo issues require targeted solutions. And because this type of drive system is always customized, it is important to choose a reliable automation partner who has full knowledge of the process or system in which the drive system is implemented.

We are specialists in the development of customized servo systems. These combine various different aspects of our expertise. In a co-engineering project, we calculate and analyze how we can significantly increase machine performance. We provide balanced advice, consisting of a combination of standard components, specific servo technology and customization. Years of experience plus the wide range of servo motors and gear units we can provide enable us to match the inertia precisely to the requirements of the machine.

We make life easier for industrial companies by creating, optimizing and maintaining high-quality servo systems.

We offer a wide range of servo components for machine builders who want to develop innovative machines.

We have extensive stocks and can guarantee short delivery times. We provide custom solutions to satisfy requirements for factors such as torque density, power and dynamic characteristics.

Select a category to read more about all the features, benefits and the different versions we provide.

Modern, highly efficient, low-maintenance and reliable servo motors.

The powerful and compact servo motors we supply are ideal for applications that require very precise positioning with repeatable accuracy, or dynamic performance.

Special servo gear units have been developed for highly dynamic servo applications.

Due to its high torsional stiffness with very low or constant rotating looseness, a servo gear unit enables working with extremely high acceleration and torque.

For top quality drive systems, we offer six precise and accurate servo drives. Each type has its own field of application and supports different types of feedback.

Our servo drives from 0.75 to 15 kW, together with servo motors and gear units, form a complete servo drive system from a single supplier.

To control and monitor the operational status of specific facilities and equipment, we supply the LS Electric XGT range of HMIs.

Developed on Windows CE, these panels are easy to use. Thanks to rapid data transmission and processing, you benefit from an effective and cost-efficient control and monitoring solution.